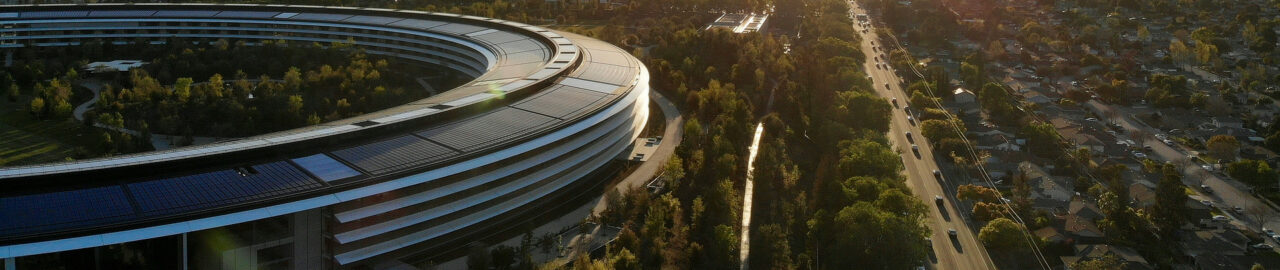

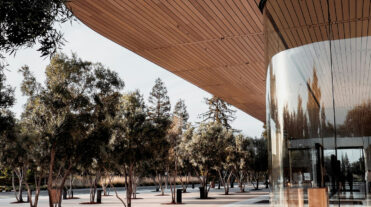

A prominent facade engineering company, involved in the construction of the new Apple Campus at Cupertino, commissioned us to deliver sealing elements for this huge project.

The first stage is the manufacture of 26 new extrusion tools, for the required seal profile geometries, by our in-house tool shop. The project also requires the production of sealing frames. This part of the contract requires us to produce several moulds for the required corner vulcanisation.

Various different types of mix are used as sealant material in the campus facade. Alongside standard mixes, we also employ special silicon-com patible mixes of EPDM. These are not only a well suited alternative to the usual silicone but, even more importantly, are more economical.

The project duration is 12 months, from start to finish. Developing solutions for the exacting tolerance limits within the profile geometries and the difficult logistics was an interesting challenge that we were only too happy to take on. Based on production and cost considerations, we decided to manufacture the products in advance and store them until requested, as needed. This gives us the capability of delivering on time, at any time.

- 26 new extrusion tools

- Special mixes of EPDM

- 12 month project duration